Boost Structural Insights with High-Accuracy Strain Monitoring

Sentra’s strain gauge series delivers precise strain measurements across pipelines, bridges, tunnels, and reinforced structures. Designed for long-term performance, the 4100 and 4150 series combine robust stainless-steel construction, waterproof sealing, and high-fidelity vibrating wire technology for exceptional stability in all field conditions.

Strain Gauges

LoRa communication for 15 km range.

Compatible with all leading manufacturers.

25 years of unattended operations.

Secure on-board storage.

Overview

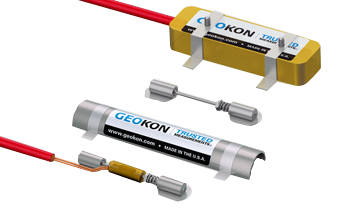

The Model 4100 and 4150 Vibrating Wire Strain Gauges are designed for measuring strains on steel surfaces or structural components where arc welding is restricted or impractical. The gauges utilize a vibrating wire element tensioned between two mounting blocks, converting even minute deformations into reliable frequency-based digital readings.

What's Included

Practical, deployment-ready components and services that make strain monitoring useful from day one

- Spot-weldable or groutable vibrating wire strain gauges for steel, concrete, or rock

- Integrated thermistor for temperature-compensated measurements

- Stainless steel, waterproof construction for long-term field durability

- Extended measurement ranges: 3,000 µε, 5,000 µε, 10,000 µε

- Detachable or integrated coil housings with simplified setup and calibration

- Compatible with GeoNet LoRa®, Cellular, Wi-Fi, and multi-channel data loggers

- Accessories: mounting kits, spot welders, epoxy bonding kits, and protection plates

Maximizing Structural Integrity with Sentra’s Strain Gauge Monitoring

Reliable, precise, and built to meet the demands of modern infrastructure monitoring.

Proactive Structural Insight

Detect early-stage stress, deformation, and load variations across steel, concrete, and composite structures for timely interventions.

Precision Strain Measurement

High-accuracy vibrating wire and MEMS strain gauges deliver stable, temperature-compensated readings across pipelines, bridges, tunnels, and rebar systems.

Intelligent Edge Analytics

On-device processing filters noise, interprets patterns, and transmits real-time data for immediate decision support.

Seamless Integration & Reporting

Fully compatible with Sentra’s GeoNet data loggers and digital dashboards for unified strain, vibration, and pressure analysis.

Main technical specifications

| Sensor type | 3-axis MEMS accelerometer |

|---|---|

| Operation modes | PPV-based and MTVV-based |

| Sampling rate | 1000 Hz derived from a 4 kHz signal |

| Noise floor | 22.5 μg/√Hz |

| Original frequency band | 0.5 – 250 Hz |

| Power source | 1 × 3.6 V D-size replaceable battery |

| Data transmission | LoRa radio communications (ISM sub GHz) |

| Operating temperature | –40°C to +80°C |

| Wireless protocol | LoRaWAN |

| System configuration | Configuration via monitoring App or remotely using GNSS Edge + GNSS Cloud |

| PPV-based operation mode specifications | |

| Reported parameters | PPV (mm/s), Acceleration (m/s²), TPV, PVS (mm/s) |

| Range | 0–40 mm/s |

| Frequency output range | 1–250 Hz |

| MTVV-based operation mode specifications | |

| Reported parameters | LAeq (dB), Lpeak (dB), MTVV, VDV (m/s¹·⁷⁵) |

| Acceleration range | ±4g |

| Linear range | ±2g |

| Frequency weighting | Wm |

| Battery life estimations | |

| Reporting parameters | SPP / SPP+ |

| 10 min | 5 years / 10 months |

| 20 min | 9 years / 1.4 years |

Got Questions? We've Got Answers.

They serve as the backbone of precision stress measurement—capturing minute deformations in steel, concrete, or rock to reveal how structures truly behave under load, temperature shifts, or external forces.

Sentra strain gauges rely on vibrating wire and MEMS technology, translating tiny material deformations into stable frequency signals. Each unit includes temperature compensation to maintain accuracy even in fluctuating field environments.

Through Sentra’s GeoNet platform. The gauges connect to LoRa®, Cellular, Wi-Fi, or Satellite data loggers, streaming clean, noise-free data directly to your dashboard or digital twin environment.

The system is engineered for endurance. When paired with Sentra’s low-power data loggers, strain monitoring nodes can run for multiple years in the field with minimal maintenance.

Absolutely. Sentra systems are designed for integrated structural intelligence—combining strain, vibration, tilt, pressure, and displacement data for a single, unified view of asset health.

Anywhere structural stress matters: welded to steel members, bonded to rebar, embedded in concrete, or anchored into rock. Common deployments include bridges, tunnels, piles, retaining walls, and industrial foundations.